Manufacture of Internal thread mold

Manufacture of

Internal thread mold

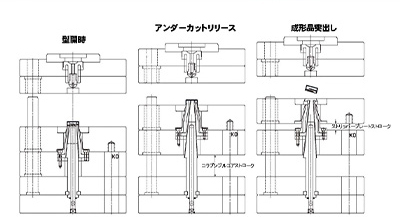

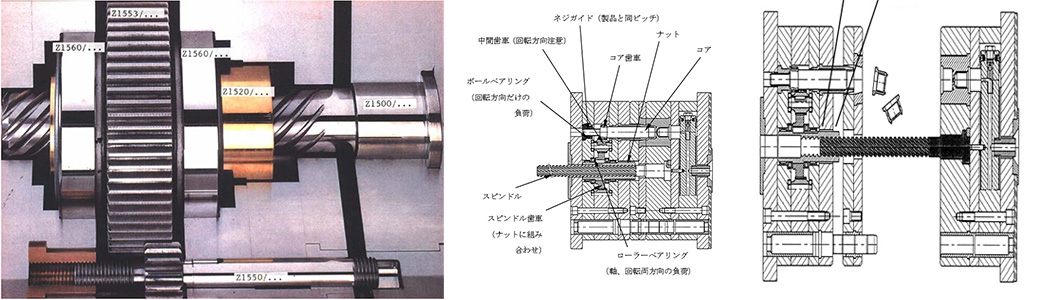

We recommend screw molds fitted with a motor for their long service life and high maintainability.

We provide production of the screw-type AC servo motors used to determine screw start and stop position, and can meet customer needs for motorless or rack-type systems.

The mold uses a general-purpose motor, and the screw stop position can be controlled by modifying the molding machine to determine the screw position of the product. Please contact us for details.

While a general-purpose motor is simply a motor that rotates, an AC servo motor controls the stop position and allows you to select the product screw position for a consistent screw mount cutout position. Rotation speed can also be set easily.

Although the product cycle is longer compared to a motorless system, these motors have a long service life and enable stable product formation.

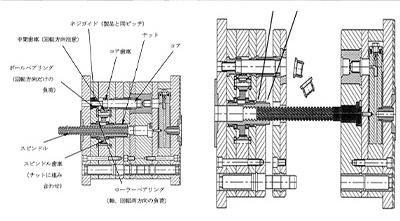

With a screw motorless mold, the screw portion detracts inside the mold and is pushed out by a stripper plate.

The problem is that since several inserts are used to contract the undercut of the screw, it can cause mold damage due to a lack of durability.

Although this structure provides a fast formation cycle, the problem is that it is expensive and subject to frequent breakage.

A screw motorless mold enables product removal by opening and closing the mold.

Mold opening and closing is conducted by a rotating spindle, which causes product removal by rotating the product.

This results in a fast production cycle but spindle peripherals are complex and expensive.